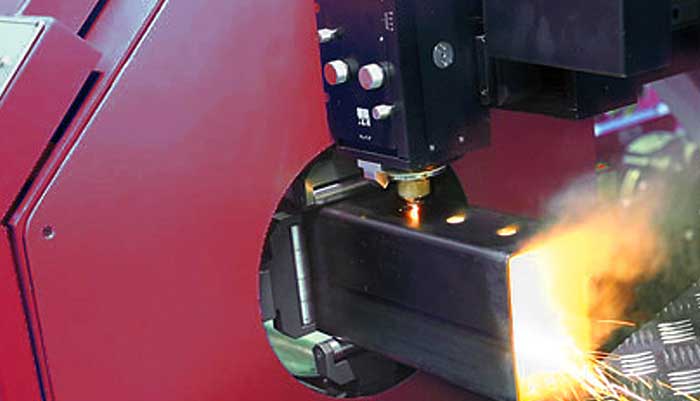

Steel Tube Lasers

How can you compensate? Traditionally, you would touch the contact points by coming down. Next, rotate the tube and touch the opposite side. This will give the control an indication about how bent the tube may be. This can be used to ensure that through-holes fit the application. Be aware that this reduces your ability to deliver very precise tolerances every time the tube rotates.

Another thing to remember is that traditional methods of checking for twists and bows in the tube may take as long as five to seven seconds before cutting begins. You have to compromise accuracy for productivity with traditional touch sensing. This can be frustrating, especially in this age of fiber laser cutting. However, working with tube is much more difficult than working with sheet metal.